Hessnatur , the organic brand from Germany had been working on the Naturindigo Selvedge Jeans Project for about 2 years with an aim to create a totally hand made natural indigo dyed jeans created by local artisans of Bangladesh. And parallel to the Fashion Revolution Day, on April 24, 2017, the first hand-woven Selvedge jeans, dyed with natural indigo and made from organic cotton was launched. The first 150 copies are numbered.

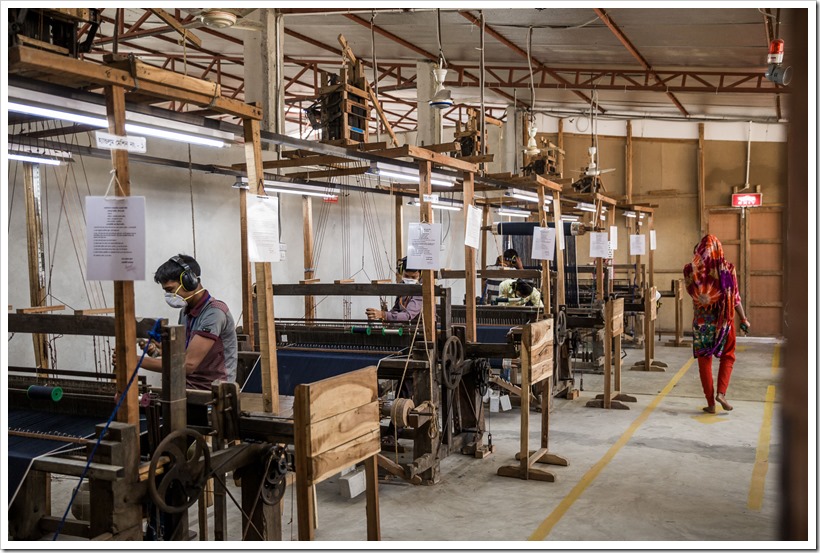

Hessnatur wanted to develop high-quality products in Bangladesh as alternative to fast fashion. For this purpose, Hessnatur has set up a production chain from the raw material to the finished denim fabric in Nilphamari together with the partners Deutsche Entwicklungsgesellschaft (DEG) and Classical Handmade Products (CHP). There the organic cotton is cultivated, the indigenous plant grows in a natural environment and the work is done in fair social conditions. A dyeing plant with five dyers as well as a weaving mill with classic hand looms were set up especially for the project. “If we want to improve the world, we have to start where things are getting worse.

In Bangladesh, we help to build on traditional strengths and show that quality jeans can be produced with respect for people, nature and the environment”, says Vivek Batra, CEO hessnatur. “Ethics and aesthetics bring people together: a self-determined life for the workers and the people who wear the jeans have a good feeling.”

Every Jeans Is Unique

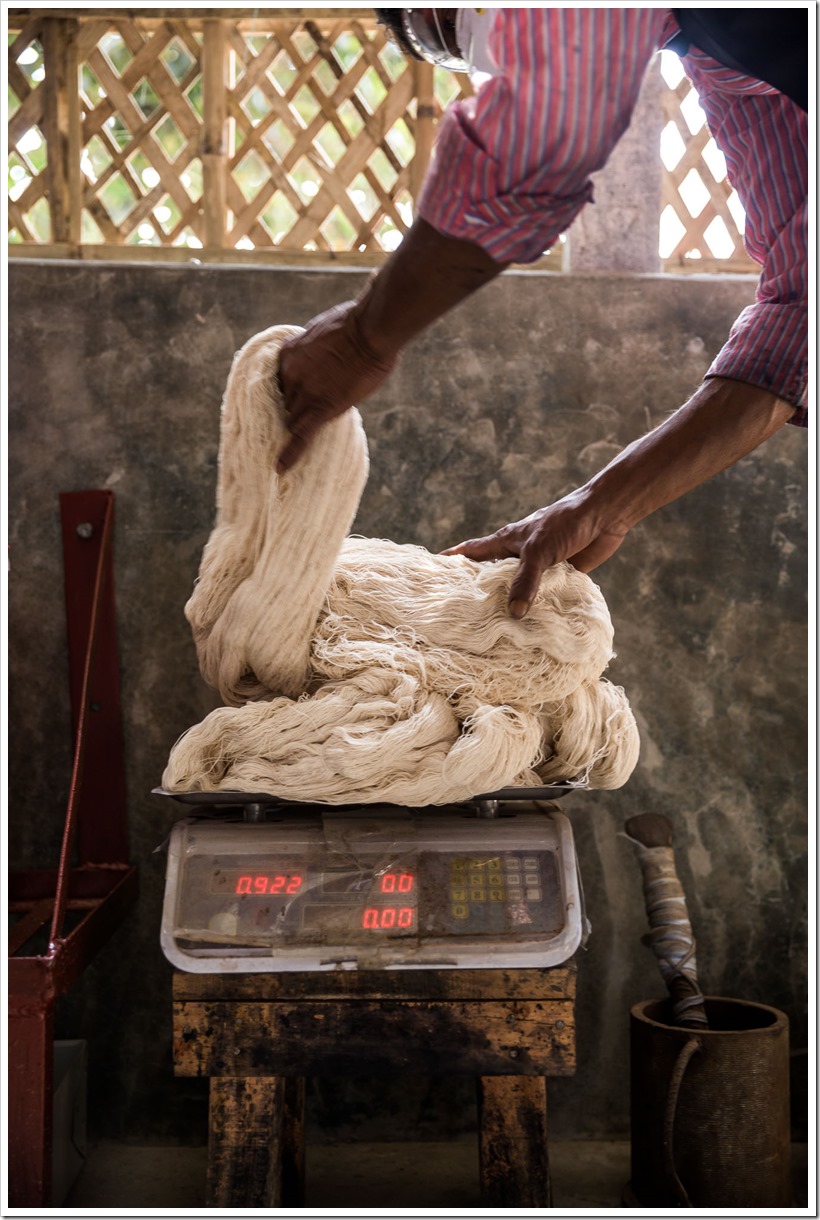

The Selvedge jeans are handmade from natural materials. That is why every jeans is a single piece. The first 150 copies are numbered to the customer. Every jeans is woven on traditional Japanese hand-looms: the fabric is softer, no sizing agents are used, since the warp threads are less stressed than in industrial processing. It takes one weaver around 10 days to prepare and weave 35m of denim fabric. 5 weavers are working for the project in total. Therefor the process is really slowing the production down, focussing on achieving high quality instead of big quantities. One weaver manages around 5 m per day. The warping and knotting process requires around 3 days of time. Indigo means the “Indian”, so the plant in the East of India grows quite originally. Bangladesh has a long tradition of coloring with natural colors. With the triumph of the synthetic colors, this experience has fallen into oblivion. The dyeing bath must be stirred one week before dyeing, a dye dyeing up to one kilogram of yarn per day, which corresponds to about two trousers.

Throughout the whole project time the workers and management of CHP received regular trainings through CSI Consulting and the local Awaj Foundation on different topics like Social Standards, Workers Safety, Chemical Management and Environmental regulations.The denim fabric is now available for other brands as well through Classical Handmade Products, as the main idea is to keep the production running and hopefully even expand it to create more jobs in this rural area of Nilfamari.

Short Distances, Competence Building In Bangladesh

The hessnatur selvedge jeans project in Bangladesh provides concrete improvements in the living and working conditions of the people working there. The social project in Bangladesh, launched with substantial investments by hessnatur, provides a model for other companies and shows that fair trade is also commercially suitable in Bangladesh. In contrast to fast fashion hessnatur manufactures in Bangladesh according to traditional production methods and contributes thus to the preservation of the country’s existing crafts competencies. For the market entry, the high-quality indigo fabric is exclusively available for hessnatur. Subsequently, other companies can also access the material.

Slow fashion at its best

In Bangladesh, indigenous plants are cultivated in fruit crops. Nitrogen accumulates in the soil. The farmers profit directly from the indigo cultivation and in the following harvesting season also a higher yield of other vegetables or fruits. The natural indigo is extracted from the leaves (indigofera). The leaves are placed in a water bath and ferment there. By continuous striking, oxygen is supplied. The dark blue water-insoluble indigo is formed from the water-soluble, yellow dye Indican. The finished indigo is dried as pebbles or liquid processed. The hand-dyed yarns are finally woven on traditional hand-looms.

Features Of This Jean

• Craftsmanship

• Traditional hand looms

• Local indigo cultivation

• Dying with natural indigo

• Classic selvedge Jeans

Every jeans is currently numbered and I was lucky to receive the Jeans No. 75 for myself (thanks Hessnatur , thanks Marina) . The jeans are extremely soft and comfortable to wear . The color is redcast with the natural indigo playing its part to give the soft raw look without any excessive washings done. Looking forward to it becoming more lively in few months with my daily routine impressions and would be happy to post how its looks change over the time !. Those looking to buy the jeans might visit this link .

By combining desirable fashion with sustainable actions, hessnatur has become a global pioneer in terms of improving ecological and social standards in textile production. Founded by Heinz and Dorothea Hess in 1976, the company launched the first natural baby collection and was globally pioneering in setting up the first organic cotton cultivation project in 1991. Today, hessnatur has around 370 employees and, in addition to its online shop and mail order business, operates stores in Butzbach, Berlin, Düsseldorf, Frankfurt, Hamburg and Munich. The world’s leading supplier, it provides a range of fashion garments, home textiles and baby clothes to around one million customers in Europe.

Meet the Global Denim Experts at the Second Edition Of Denimsandjeans Vietnam to be held on June 7-8