Covid times has brought out great challenges to the global denim industry in recent months. It has forced all of us to think about how we can adapt in the new environment and adjust to the new normal . We have been speaking to some of the important companies around the world on how they adapted their work procedures and processes to ensure minimal impact.

Denim Clothing Company is a well known and reputed vertically integrated denim company from Pakistan and has been serving global clients through their fabric and garment divisions . It currently operates four factory units and employs about 8,500 people.They have been known for their fast innovations and product launches and adaptability with a focus on sustainability . We spoke to the Director, Machiyara Group – Mr. Munaf Hussain on how he adapted his company to ensure that they could continue to serve their clients well and provide best possible services to them .

Given below are excerpts from the interview we had with him.

How is Denim Clothing Company (DCC) catering to its customer base in the current situation when travel is not possible. Are you able to reach out to them effectively?

The pandemic and ensuing lockdowns have enabled DCC to utilise our digital platforms more effectively. We have managed to push toward and explore new venues for digital communication to achieve an interactive experience with our customer base. Our marketing department is constantly meeting customers via video calling software, and we have switched digital product presentations.

Additionally, we have a network of our foreign offices / showrooms globally, all of whom are invested more than ever in facilitating our clients where physical meetings are unavoidable and filling up any communication constraints. Our new collections are available at our showrooms and can be delivered to customers in a very short time span. Again, this is very feasible for both ourselves and customers – delivery times are drastically reduced since the products and samples are easily accessible.

Your steps are in the right direction. Digitalization is the new keyword for business today. What further steps have you taken to take your products digital and bring them to your customers?

We have managed to very quickly adapt and implement a digital structure for communications – our showrooms both at the factory and globally are fully equipped to carry out digital presentations, whether live or as pictorials, with the latest software and technology. There are dedicated conference rooms for both individual and team video conferencing), again employing up to date tech setup for video calling.

DCC has switched to creating E-catalogues of all our new collections, with high resolution images and detailed product sheets. In this way, customers can simply browse through the information at their convenience and then the process can be facilitated via video conferencing. For more detailed product perusal and information, samples are readily available at all our showrooms and can be dispatched when needed.

You have been putting in efforts for sustainability for a long time. What are the major steps you have taken in this direction and what have been the results?

All our present and future developments are visualized with a sustainability focus in mind. We have placed immense efforts in this arena and taken some major steps across the value processing chain.

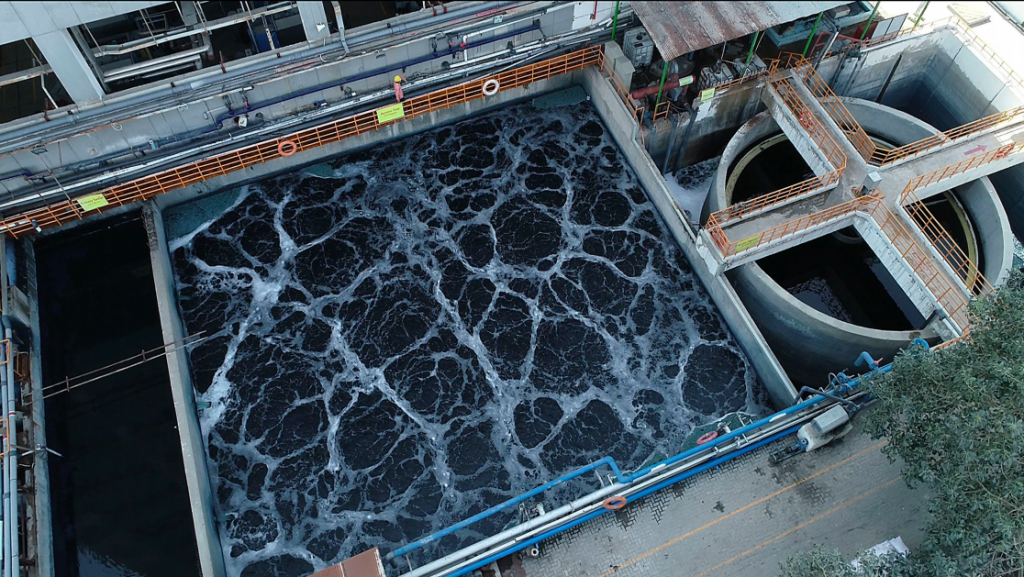

Since the establishment of our factory, we have proceeded to install a WasteWater Treatment Plant, and we are mindful of maintaining and updating the plant according to the latest health and safety advisories. Currently, we recycle about 50% of our processed water and reutilize it, thus conserving this precious resource.

We take great importance in utilizing Recycled Content Fabrics as well as Organic Fabrics along with Sustainable Dyeing methods to ensure our commitment to a circular economy.

In terms of operations, our latest feat is securing a Leed Gold Certification for our production facility, which reaffirms our commitment to being a ‘Green Factory’.

Our garment washing treatments consistently employ the latest sustainable methods, low impact washes via a state of the art Jeanologia E-flow, EIM and Laser systems, PP Less washes, anti-microbial treatment (this has taken on new meaning and importance with the pandemic onset). Our laundry setup is a ZHDC complaint, and strictly follows guidelines with respect to chemicals which are harmful towards the environment.

In terms of tangible achievements, DCC has enabled 50% recycling of all water used within the production process. Additionally, to reaffirm the reduction of contamination and dangerous chemical usage, we have minimized our consumption of stones in the laundry process.

Our aim is to move steadily towards a Zero Liquid Discharge (ZLD) system and doing our part in reducing the textile industries’ carbon footprint. In this respect we continuously implement and improve the EMS system to improve our working processes. Also to watch out for is our plan to introduce the capability for an Ozone Bleaching System, which is being finalized through our research and development team.

What sustainability programmes are you subscribed to?Please share some ideas on the certifications and approvals that you received towards sustainable initiatives.

For our fabric division we are currently certified with:

- HIGG FEM 3.0

- ISO 14001

- OEKO Tex 100

- Oeko-Tex STeP

- Made in Green

- GOTS

- Global Recycled Standard

- Content Claim Standard

- Organic Content Standard

- Recycled Claim Standard

- BCI

And for the Garments Division:

- HIGG FEM 3.0

- OEKO Tex 100

- STEP Certification

- Made in Green

- BEPI

- ISO 14001

- EIM Score

- ZDHC Compliance

- GOTS & OCS

- GRS / RCS

How is your product development process going ? How are you able to react to requirements of your customers when it is not easily possible to do physical things like sampling / travelling etc. Are you able to meet customer needs?

Our diverse and multi-nationally located team have become our core strength in these times. We have always pushed ourselves in various directions to come up with new ideas and concepts in order to meet various customer requirements, and the present is a similar challenge for our team. Overall, our product development process is quite effective at the moment, customers are buying from the backlog which had been created during lockdown. New selections for order are being carried out through digital catalogues / images.

Speed and turnaround time are other keywords which are getting important in the context of the current situation. How have you adjusted your procedures and processes to be able to reduce the lead time for your customers?

Currently as you know, the entire buying as well as supply cycles have been disturbed. However, things are slowly beginning to improve with the easing of lockdowns and gradually the pace is increasing. However, we are conscious of not doing too much too fast – health and safety of our employees remains our top priority and we are careful in resuming production keeping in view the latest scientific guidelines.

As stated above, we have complete confidence in our local and international teams to ensure customer satisfaction, and employ technological aids to their fullest in order to reduce hassles due to travel and movement restrictions.

Contact Denim Clothing : Info@denimclothing.biz