Crystal International Group Limited, a prominent player in the global apparel manufacturing industry, is taking bold strides towards circularity with its latest venture, the Renewcell Circulose Supplier Network. Teaming up with Renewcell, a Swedish textile recycling company, Crystal International is spearheading the movement for circular development in the fashion world.

Founded in Hong Kong in 1970, Crystal International Group Limited has a diversified product portfolio and a multi-country manufacturing platform, Crystal International serves leading global brands through a highly differentiated “Co-creation” business model. The Group maintains a keen focus on sustainability and aims to achieve its Crystal Sustainability Vision 2030 and Net Zero 2050 Vision, positioning itself as a driving force for positive social and environmental contributions.

Renewcell

Renewcell, a pioneer in textile recycling innovation, has introduced the CIRCULOSE® Supplier Network (CSN) – a group of forty-seven yarn and textile producers dedicated to advancing the circular economy by ensuring a steady supply of CIRCULOSE® to the market.

Crystal International Group Limited is among the leading companies partnering with Renewcell in this initiative.

Crystal International’s Role in CSN

Crystal International’s collaboration with Renewcell in the CSN aims to ensure a consistent supply of CIRCULOSE® to the fashion industry, fostering circularity in textile production. And also commits to the continuous development of circular solutions, contributing to sustainable textiles and end-products under the CIRCULOSE® brand name.

Empowering Circular Economy in Fashion

CIRCULOSE® is a revolutionary Next Generation raw material derived from recycled cellulose found in worn-out clothing. Renewcell’s pioneering process transforms this into dissolving pulp, serving as the foundation for various regenerated fibers. Crystal International and other CSN members lead the way by streamlining CIRCULOSE® production across the supply chain, allowing fashion brands to access circular options for designing and creating clothing with CIRCULOSE®.

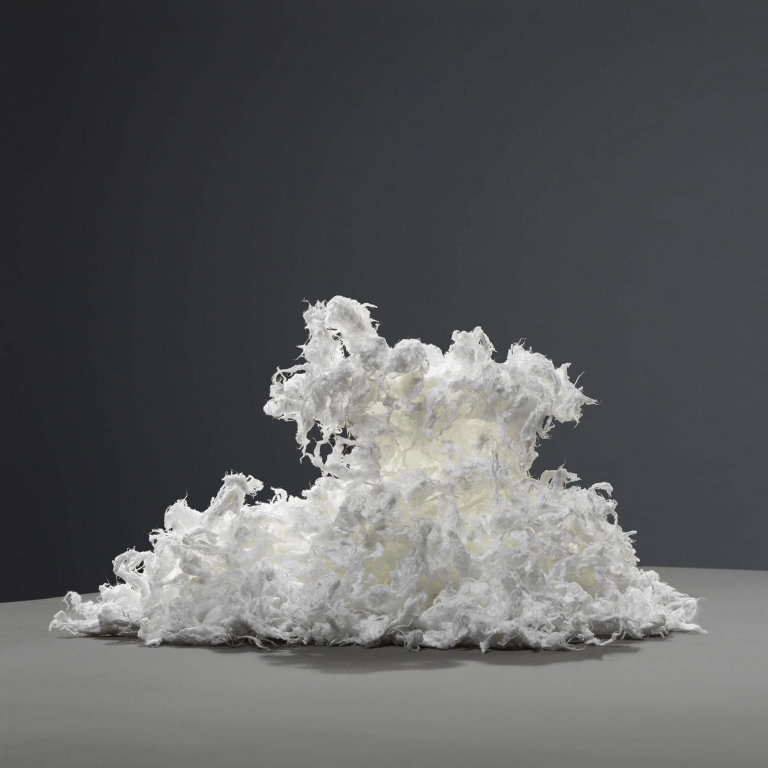

A Transformation Process: CIRCULOSE® is transformed into dissolving pulp made from 100% recycled textiles, forming the foundation for different regenerated fibers, including viscose, lyocell, modal, acetate, and other man-made cellulosic fibers. The recycling process involves shredding, de-buttoning, de-zipping, de-coloring, and turning discarded textiles into a slurry, which is then dried to produce pure CIRCULOSE® sheets. Renewcell’s commitment to using 100% renewable energy in the production process has earned them various sustainability certifications with good traceability.

Crystal International’s collaboration in the CIRCULOSE® Supplier Network marks a significant milestone in the circular economy advancement. By partnering with leading yarn and textile producers, CIRCULOSE® aims to transform the fashion industry, paving the way for a circular future in the fashion supply chain. The commitment to sustainability and circularity strengthens Crystal International’s position as a driving force in promoting positive change within the global apparel industry.

Check out Special Denim Export and Import Data Reports to Glean Insights on Global Markets

Top Vietnamese Denim Companies Using Pakistani Fabrics In 2023

Top Turkish Denim Companies Buying Pakistani Fabrics In 2023