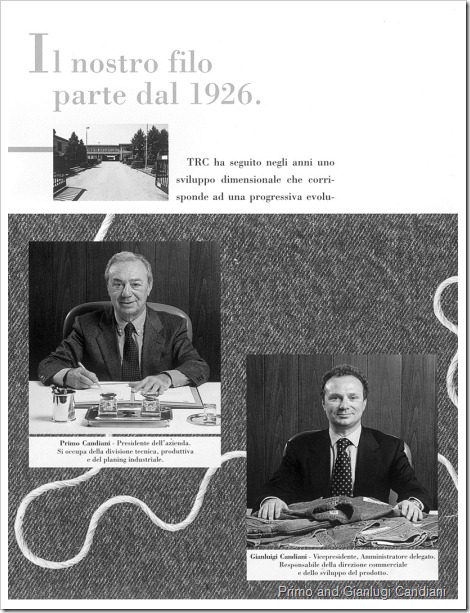

Q.Pl tell us something about the history of TRC .

Candiani’s history is our family history. It all began with Mr. Luigi Candiani who bought several looms back in 1938. At that time we were weaving workwear fabrics and sold

The company has always invested in new technologies and innovation. Yarns went back to "Ring", slasher dyeing got closer to the wrap system and GianLuigi moved the focus on the development of a good looking and performing stretch Denim.

In the second half of the 90’s exports overtook the domestic business, the company became global and 100% product driven. In 2005 we increased our capacity investing in a superior spinning department which made us completely self-sufficient in terms of yarns supply.

Today Alberto Candiani, the 4th generation, together with his father GianLuigi are challenging the industry by taking Denim to the next level every season.

Q.TRC – Candiani is one of the strongest brand in denim industry worldwide. While so many other European denim mills faded away, you have emerged stronger. What makes Candiani so vibrant and dynamic ?

I believe the reason is our structure and our strong innovations. We are a family owned business, with a very small management and decision making, and we are proud to consider ourselves "oversized artisans" instead of a sort of textile corporate.

I think our product and our service are the key points of a successful business.

Q.I believe this is the third generation from Candiani which is running the show . What changes you have seen in the last 30 years as denim evolved from a workwear to a fashion product, from an OE to a primarily ring product ?

This is actually the 4th… We can easily focus on some points which describe the rise of Denim and the transformation of a pair of Jeans in a fashion item:

- From Open End to Ring

- Deeper dyes and versatile colors which gave the opportunity to treat the Jeans in the second step: the laundry.

- The advent of stretch Denim and the creation of a Women Premium Industry.

- More compact constructions

- Fancy finishings

- Sustainable products.

Q.You are very strong in innovations and denim brands around the world vouch for your quality . You are personally so deeply involved in the development process. The knowledge base that you have developed over such a long time must have really helped you to innovate so well.

In the end that’s still the most fun part of my job: creating the product, Denim. We need to experiment a lot, we need to invent, not to follow trends. That’s why I always pay attention to other segments of the textile industry too.

What is also very important is to have a direct and transparent relationship with the brands’ designers and with our suppliers.

Q.Can you tell us about some denim products from your mill’s history which have been a great success and still inspire you.

Well, there were a few of big OE items I can’t really remember because of my young age…

Let’s say that the fabric that has changed our philosophy was designed by my father GianLuigi and Mr. Austoni (our GM) at the end of the 90’s.

It was called, or it is called (cause we are still selling quite a lot of this fabric today) RR 7070 Ink Shiny and RR 7008 Ink Millennium in its stretch version.

This item is pretty much an open weave construction, 3 by 1, around 12 Oz, with multi-twisted yarns in the warp which give a nice authentic look to the construction, in a deep grey cast indigo, flat optic finished.. and the stretch version made the difference since our recovery has always been considered the best in the market.

A more recent item, developed in 2005, has been RR 1532, a finer, lighter and more compact construction compared to the previous one, which came in different colors and finishes, with a pretty marked crosshatch effect.

I believe we sold over 50.000.000 mts in these two constructions.

Q.Pl tell us about your SS ‘15 denim collection

It looks like authentic Denim is finally coming back. When I say authentic I am mostly talking about the Ring character and the red cast deep indigo shades.

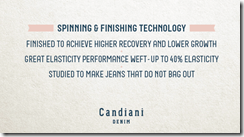

In our specific case the new stretch technologies are the core of our business and our performance stretch technology (from comfort to power) is re-defining a new standard in the market.

Good elasticity and recovery are everything for women’s Jeans, together with soft hand, which does not have to be drapey, cause the Jeans have to hold you in.

We also developed a big family of comfort stretch fabrics which you will

Alternative finishings are still big, from pigment or sulfur foam to the classic coating, but we are trying to re-interpret them in a waterless way.

Sustainability is taking more and more space in this collection, our consumption of Organic and BCI cotton is growing exponentially as much as the use of our Recycled Cotton Yarns.

7. Europe must still be the most imp market for you.. But the recent recession and drop in European sales has affected all. Do you see Europe doing better in near future?

Actually yes, I am pretty positive. Europe does not mean Italy of course. Our Country is unfortunately suffering more than others (for too many reason) and it will take longer to recover.

Hopefully Europe and US will understand they have to cooperate and establish a duty free relationship, it really makes sense in 2013.

8. Denim in the 80s and early 90s was mainly OE . We then saw the shift back to Ring denim. Do you think there is any possibility of OE being reinvented and reborn?

Not as much maybe but I am convinced that our latest stretch technologies are setting a new benchmark.

Considering that women’s skinny Jeans are still the main item in our market I can say that there is no way to make a sexy pair of Jeans without taking this direction in combination with a nice touch and color.

Follow Denimsandjeans on Facebook and get the latest in denim trends worldwide – daily !!