Nandan Denim Limited

About The Group and Mill

Commenced in 1994 with textile trading business,Nandan Denim is One of the largest producers of Denim in India, poised to be the largest manufacturer in Asia, 4th largest in the world. Its Head Office & Marketing centralized at Chiripal House. The Manufacturing Facilities at Piplej & Bareja in Ahmedabad .Company claims its share of Domestic Sales is 80 % & that of Export is 20 %.Currently the company exports to 27 countries.

Expanding denim fabric capacity from 71 MMPA to 110 MMPA in FY 17.Expanding Spinning capacity from 64 TPD to 124 TPD in FY 17

According to company officials ,

Our mission here is, “To emerge as the largest and most profitable denim manufacturer in Asia ,be a preferred customer for the vendors,be a great place to work and grow with the organization,be a preferred supplier for the valued customers, be the first brand to re-call,Paperless, transparent, pre-defined system,Most valuable denim fabric brand.â€

ADVANTAGE – NANDAN

-

Poised to be the biggest denim manufacturer in Asia

-

Diversified portfolio including Yarn, Dyed Yarn, Shirting, Khakis & Denim

-

Vertically integrated to insulate in case of downslide

-

Flat organization structure for quick decisions & communication

-

Latest Technology & Machineries sourced from across the globe

-

Robust Quality check systems

-

In house creative design studio & Product Development Cell with experts having understanding of latest trends

-

We love experiments with fashion, breaking old rules of fashion and defining new ones

-

IT-enabling. We run on SAP

-

Strong Financials

Product Range –Current Focus

Nandan denim’s mission is to become preferred customer for the venders. For that company is producing and supplying all kinds of denim fabric , starting from 2.5 osy light weight shirting denim to 15.0 osy basic denim. All kinds of fiber blends, weaves, finishes, prints are core products.

AW17/SS18 Products

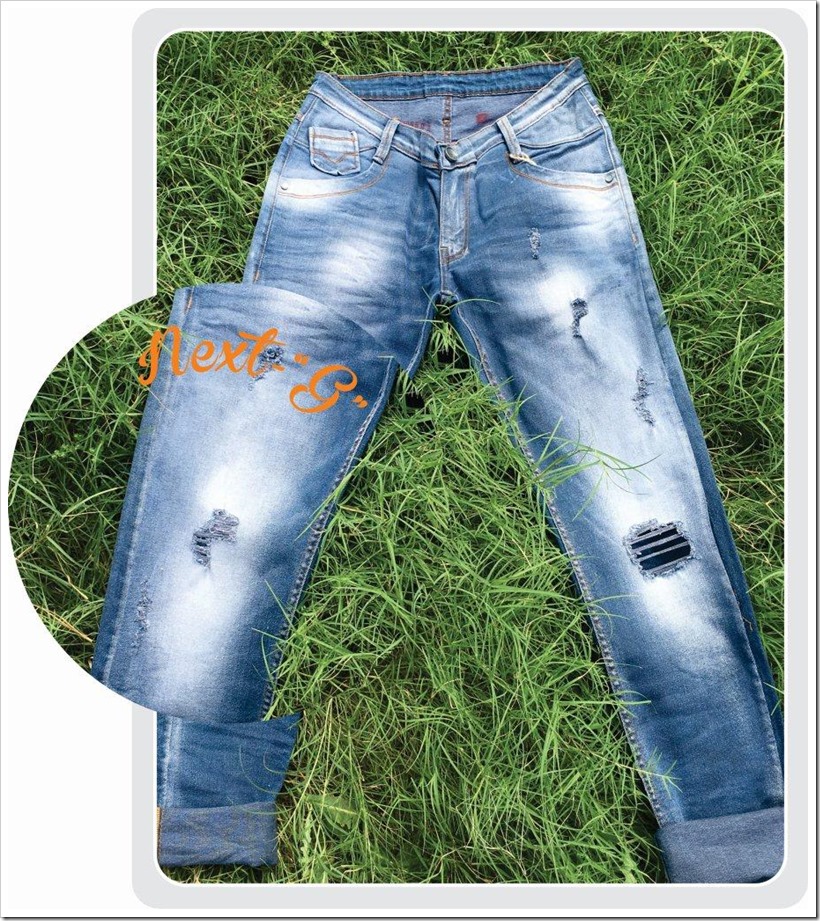

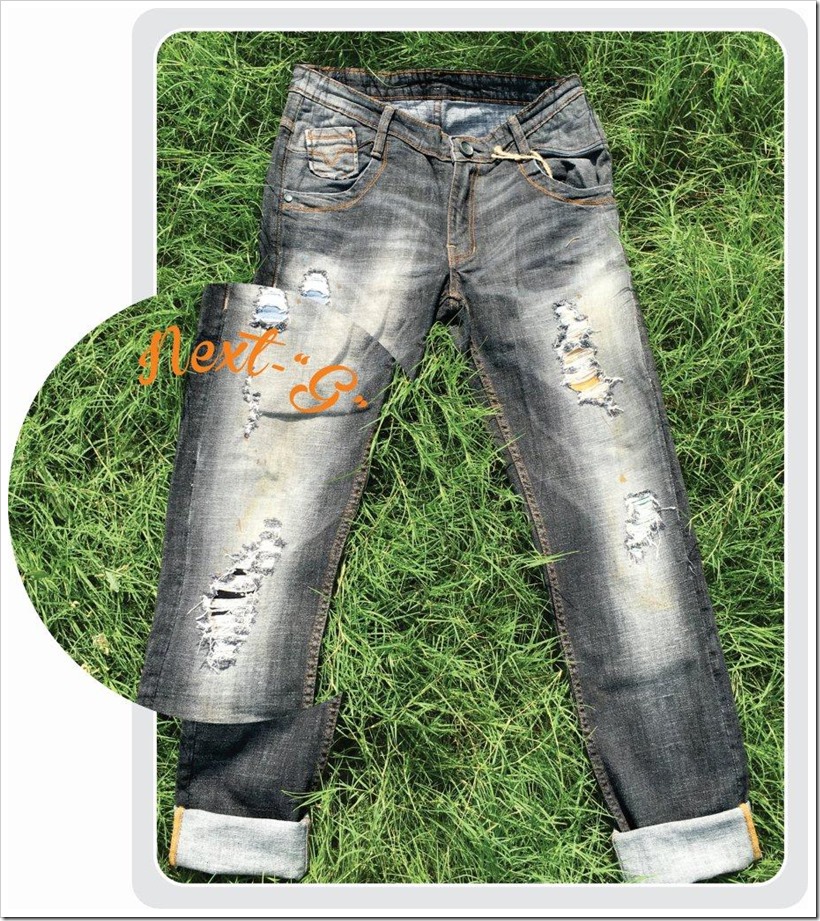

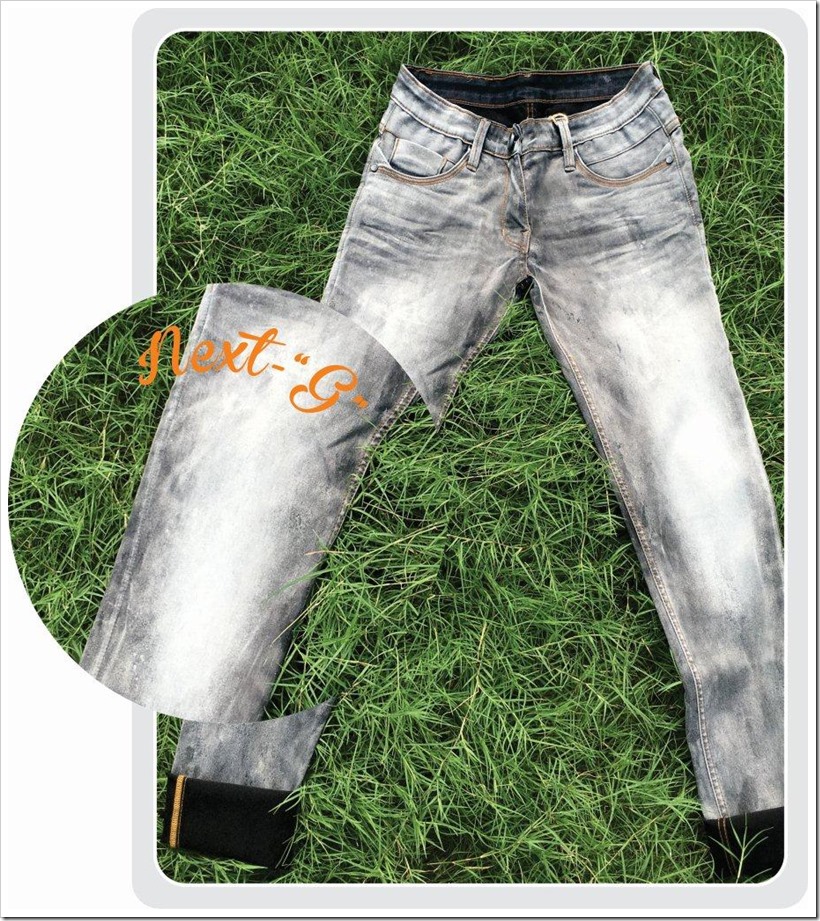

NEXT-G’

-Special finish denim with different shades in different weight. All are with very low weft shrinkage for better control in garmenting. Saturated indigo looks take inspiration from traditional, natural indigo-dyeing methods such as baked indigo and rich dry indigo coatings. These applications allow for high-contrast wear lines such as back pocket templates, cracked lines and uneven retention. bromo indigo is one of that to give you a new brighter shade of indigo

Performance denim

Duel core denim for better recovery at good stretch. Romance between Authentic Core Denim and their new face for your comfort with its amazing recovery capacity, Performance Denim is a unique fabric featuring dual-core yarn technology in which two-component yarn patented technology for greater elasticity and lasting conformal jeans

Rubber stretch

Power stretch denim . Getting the right fit is everything. You either want comfort or you want to look really smart, sometimes both. Our aim has always been to cover all bases in terms of fits. We offer the POWER STRETCH denim fabric. Suffice it to say, there’s something for everyone.

Compuss denim

Two way stretches in different weave and shades. Advances in stretch technologies keep the skinny jean relevant. Smart fabric designed using the highest technology and special blends in both warp and weft offer multi-directional elasticity, while optimum recovery ensures a silhouette that retains impeccable form.

Craft-D’

Light weight shirting denim in different fiber blends, structure and finishes.Deep, intense indigo shades capture the raw surf spirit for both casual and smarter denim items. Subtle artisan all-over and banded patterns and textures enrich.

Sustainability Technique Used In Production

The company Says ,

“Sustainability is the future . Company as it’s core value, constantly invest in sustainable process. Zero discharge effluent one such example.Re-cycle and re-use of process waste like cotton, caustic, water etc. are regular core process.As a Sustainable denim , company is using alternative fiber like Tencel denim, lenen denim. “

Immediate Future Growth Plans

Nandan denim as a company and Chiripal group as a whole is investing huge amount of money in all segments :

-

Spinning capacity. From 64 MT per day to 124 MT per day. Company is venturing into all kinds of yarn spinning like blended yarn ( cotton/ tencel, p/c/spandex, P/V/Spandex), finner counts, compact yarn, melange yarn, fiber dyed yarn and many more.

-

Weaving capacity. 71 MMPA to110 MMPA . The new expansion will be catering to all kinds of weave design and any width required by the constantly changing fashion market.

-

Dyeing capacity. 84 MMPA to 110 MMPA. The company is capable of doing any kinds shades with any yarn.

-

Value added finishing : Flat finish, over dyeing ,and in many other special finishes.

Market Focus

The company claims to have a strong dealer network spread across the world to enable easy and timely availability with direct contacts available in Hong Kong, Bangladesh, Egypt, Peru, Panama, Columbia and Korea. The mixing of international customers with the domestic customers enables Nandan to mix the two different streams of cultures, brining world to India and taking India to the world.

Though present main market is Indian domestic market, Nandan denim supply denim in almost 27 countries. Now focusing more on exports markets like USA and Europe.Other areas like Bangladesh, Vietnam, Latin America etc.

Suggestions For The Industry

Industry needs to think seriously and implement alternate process of garment washing to save water.