1.BROKEN STITCHES – NEEDLE CUTTING

Description : Where the thread is being broken where one seam crosses another seam (ex: bartacks on top of waistband stitching, seatseam on top of riser seam ) resulting in stitch failure.

Recommended solution by A & E :

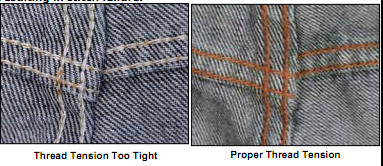

- Use a larger diameter thread on operations

where the thread is being cut. - Make sure the proper stitch balance is being used. On a chainstitch seam on denim, you normally would like to maintain a 60%/40%

relationship of Needle thread to Looper thread in the

Seam. - Use needles with the correct needle point.

- Change the needles at regular intervals on operations

where the Needle Cuts are occurring frequently. - Use a higher performance Perma Core or D-Core thread.

2.Broken Stitch – Abrasion :

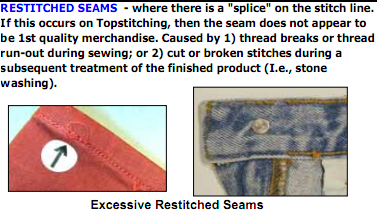

Description : where the thread is broken during stone-washing, sand blasting, hand sanding, etc. Broken stitches must be repaired by restitching over the top of the stitch-line.

Recommended Solution :

- Use a larger diameter thread on operations where

excessive abrasion is occuring (ex: use T-120 on

Waistband); - Make sure stitches are balanced properly.

- Use a Magic air entangled thread in the looper due to its lower

seam profile making it susceptible to abrasion

(ex: use T-90 or T-135 Magic in loopers of the Yoke, Seat

and Waistband seam); - Monitor the Finishing Cycle for compliance to specs.

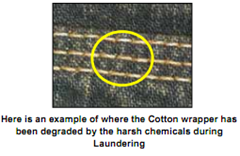

3. Broken Stitches : Chemical Degradation :

Description : where thread is being compromised by the chemicals used during laundering resulting in loss or change of color and seam failure.

- It is recommended to go to larger thread sizes when the

Denim Garments will be subject to Harsh Chemical

washes. - To achieve the best laundering results make

sure that the water temperatures and PH Levels are

correct and that the proper amounts and sequence of

chemical dispersion are within guidelines. - Make sure the garments are being rinsed properly to neutralize the

chemicals in the fabric. - Monitor the drying process, cycle times, and temperatures to make sure they are correct so that the best possible garment quality can be

achieved.

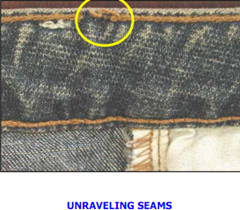

4. Unravelling Seams :

Description : where either the stitch has been broken or a skipped stitch has

occurred. This will cause seam failure unless the seam is Restitched.

Recommended Solution :

- This may include going to a higher

performance thread designed to minimize sewing

interruptions. - Observe sewing operators for correct

material handling techniques.

6. Sagging or Rolling Pockets :

Description : where the pocket does not lay SAGGING OR ROLLING POCKETS flat and rolls over after laundering.

Recommended Solution :

- Make sure the sewing operators are not holding POCKETS

back excessively when setting the front pocket. - Make sure the hem is formed properly and that excessive

fabric is not being being put into the folder that will cause

the hem to roll over. - Check to make sure pocket is cut properly and that pocket curve is not too deep.

- Use a reinforcement tape on the inside of the pocket that may

help prevent the front panel from stretching along the bias

where the front pocket is set. - The type and weight of denim, along with the fabric construction, may contribute to this problem. Contact your fabric supplier for assistance.

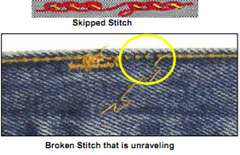

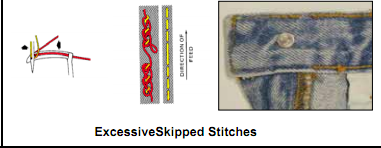

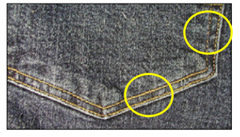

5.Skipped Stitches

Description: where the stitch forming device misses the

needle loop or the needle misses the looper loop. Skips are usually

found where one seam crosses another seam and most of the time

occurs right before or right after the heavy thickness.

Recommended Solution :-

- Use corespun thread.

- Use minimum thread tension to get a balanced stitch.

- Use the ideal foot, feed and plate that helps to minimize

flagging. - Training sewing operators NOT to stop on the

thickness. - Make sure the machine is feeding properly

without stalling. - Make sure the machine is not back-feeding.

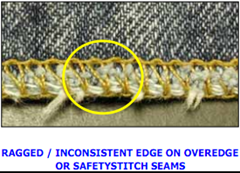

6. Ragged – Inconsistent Edge

Description : where the edge of the seam is

either extremely “ragged” or “rolls” inside the stitch.

Recommended Solution :

- Make sure the sewing machine knives are sharpened and

changed often. - The knives should be adjusted properly in relationship to the “stitch tongue” on the needle plate to obtain the proper seam width or width bite.

7. Wavy Seams On Stretch Denim

Description : where the seam does not lay flat and is wavy due to the fabric stretching as it was sewn or during subsequent laundering and handling operation.

Recommended Solution :

- Use minimum presser foot pressure.

- Instruct sewing operators to use proper handling techniques and not

stretch the fabric as they are making the seam. - Where available, use differential feed to compensate for the

stretch of the fabric.

8. Ropy Hem

Description: is where hem is not laying flat and is skewed in ROPY HEM

appearance .

Recommended Solutions :

- Instruct the sewing operator to make sure they get the hem started correctly in the folder before they start sewing.

- Also, make sure the don’t hold back

excessively as the seam is being sewn. - Use minimum roller or presser foot pressure.

9. Twisted Legs :

Description : is where the sideseam twists around to the front of the pant and distorts the appearance of the jeans .

Recommended Solution :

- Instruct the sewing operator to

match the front and back properly so they come out the

same length. Sometimes notches are used to insure proper

alignment. They should NOT trim off the front or back with

scissors to make them come out the same length. - Make sure the cut parts are of equal length coming to the

assembly operation. - Check fabric quality and cutting for proper skew.

- Make sure the sewing machine is adjusted

properly for uniform feeding of the top and bottom plies

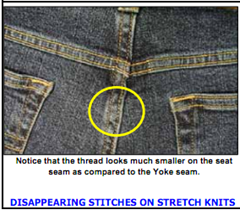

8. Disappearing Stitches in Stretch Denim

Description : is where the thread looks much smaller on seams sewn in the warp direction than in the weft direction of the fabric

Recommended Solution :

- Use a heavier thread size (T-120, ON STRETCH DENIM

T-135, T-150) on topstitching. - Go to a longer stitch length (from 8 to 6 spi). 3) Make sure the thread tensions are as loose as possible so the thread sits on top of the

fabric rather than burying in the fabric on seams sewn in

the warp.

10. Thread Discoloration after Laundry

Description : is where the thread pics up the indigo dyes from the fabric giving the thread a ‘dirty’ appearance. A common discoloration would be the pick-up of a greenish or turquoise tint.

Recommended Solution :

- Use thread with proper color fastness characteristics.

- Correct PH level (too low) and Water Temperature (too low) during

laundry. - Use the proper chemicals & laundry cycles.

- Use Denimcol PCC in wash or similar additive.

- Do Not overload washers with too many garments at one time

Need further info on denim stitching , visit A&E website or contact them.