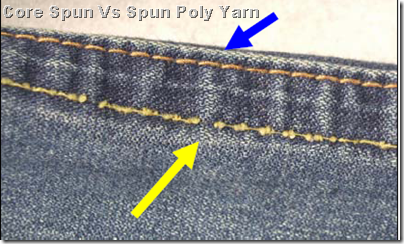

American and Efird brings out an interesting comparison between Corespun and Spun Threads to help understand the difference between the two better and the reason why corespun gives better results in denim sewing .

What are Corespun Threads ?

- Higher strength per size (higher tenacity)

- Greater uniformity in size, strength and other physical characteristics•

- A higher initial modulus or resistance to stretching contributing to better loop formation and reduced seam puckering.

- Better ply security – fewer unravel type thread breaks

- Superior abrasion resistance & durability

The wrapper of a corespun thread can be either staple polyester or staple cotton. The wrapper gives the thread a fibrous surface that contributes to:

- A softer “hand” or feel than a 100% continuous filament threads

- A matte finish stitch appearance similar to a spun thread construction

- Superior frictional characteristics compared to a continuous filament threads

The Poly wrapper contributes to :

o Superior color fastness, chemical and abrasion resistance

o Higher strength than cotton wrapped corespun threads

o Superior “union dyeing” because of one-step dyeing process

The Cotton wrapper contributes to :

o Superior needle heat resistance

o A “wash-down” stitch appearance

What are the benefits of using core spun yarns on denim ?

Corespun threads (eg Perma Core®NWT) are :

- 40 to 50% stronger than spun polyester threads the same size

- Superior sewability on both manual and automatic machines with minimum interruptions – fewer restitched seams.

- Helps to Minimize Open-Seams and Seam Failure

- Allows the use of smaller diameter thread to minimize Seam Puckering or Needle cutting

- Helps to minimize broken and cut stitches after finishing.

Spun Polyester Threads (PP Threads) – An Analysis

Spun Polyester threads, sometimes referred to as “PP” or “PP Spun”, are made by spinning 100% polyester staple fibers into yarns and then plying these yarns into a sewing thread. Spun Polyester threads are normally made in a two or three ply constructions depending on the yarn size. Spun polyester threads generally have much lower single end breaking strength than corespun threads. A comparison below of two products – a corespun and a spun polyester thread from A & E brings out some facts :

Core Spun Vs Spun Polyester Yarn – Technical Specifications

Here are some technical specifications of two yarns from the same company – one Core Spun and the other Spun Poly – to find out some differences between the two.

| Tex Size | T-18 | T-24 | T-30 | T-40 | T-60 | T-80 | T-105 | T-120 |

| Yarn Size | 59/2 | 45/2 | 35/2 | 29/2 | 18/2 | 15/2 | 12/2 | 15/3 |

| Av. Strength(lbs) | 2.1 | 2.7 | 3.5 | 4.5 | 7.8 | 9 | 10.6 | 13.51 |

| Elongation (% at break ) | 21.5 | 20.5 | 21.5 | 21.5 | 24.2 | 24.8 | 26.3 | 25.7 |

| Shrinkage (BW) |

<1% | <1% | <1% | <1% | <1% | <1% | <1% | <1% |

| Shrinkage (HA) |

<3% | <3% | <3% | <3% | <3% | <3% | <3% | <3% |

| Loop Strength (lbs) | 2.7 | 4.0 | 5.2 | 6.3 | 11.6 | 13.3 | 15.8 | 20.5 |

Perma Spun® – Poly Spun Yarn

| Tex Size | T-21 | T27 | T-40 | T-60 | T-80 | T-105 | T-120 |

| Yarn Size | 53/2 | 43/2 | 29/2 | 19/2 | 14/2 | 16/3 | 16/4 |

| Av. Strength(lbs) | 1.6 | 2.1 | 3.2 | 4.7 | 7.1 | 9.7 | 10.6 |

| Elongation (% at break ) | 16.1 | 16.3 | 17.0 | 18.0 | 18.6 | 19.9 | 18.5 |

| Shrinkage (BW) |

<1% | <1% | <1% | <1% | <1% | <1% | <1% |

| Shrinkage (HA) |

<3% | <3% | <3% | <3% | <3% | <3% | <3% |

| Loop Strength (lbs) | 2.7 | 3.1 | 4.8 | 7.9 | 11.3 | 15.1 | 16.9 |

As can be seen from the specifications, there is a significant difference in strength of the core spun and spun polyester yarns, even though they have been manufactured by the same company. Local spun polyester yarns could have still lower strengths raising the possibilities of increased sewing ruptures after washing.

Cost Vs Performance

Core spun yarns are definitely more expensive than the spun polyester yarns. The usage of these yarns can increase the cost of production . However, using spun polyester yarns can increase the possibility of broken stitches and rejected garments or needing repairs.

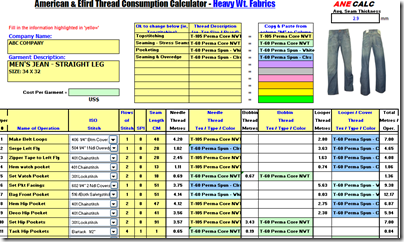

A & E mentions that certain manufacturers have tried to use both Core Spun and Spun Poly to achieve a balance between costs and performance.

Since overedge seams consume the most thread, they will used spun polyester on these operations while continuing to using corespun threads on all topstitching and stress seam operations.

If you are using a combination of different threads, you can find the total thread cost per garment by using the ANECALC from the company. This calculator will help to find the total thread cost per garment – though it will not give the thread cost saved or made due to performance of sewing thread. Click on the image below to download the calculator for Men’s Jeans – heavy weight fabrics.

For other calculators related to Men’s Carpenter Jeans , Ladies Jeans, Missy’s Jeans, Kids Jeans and Kids Carpenter jeans (both in yards and mtrs) go to this page and download (under the heading ANECALC APPAREL GUIDELINES).

Also check ‘How to sew extra heavy threads in sizes in denim jeans ?”