Ramsons Garment

Finishing Equipment’s Pvt Ltd

Denimsandjeans spoke to Sunder Belani – Managing Director of Ramsons Garment Finishing Equipments Pvt Ltd and tried to understand their efforts towards sustainability and their latest machines and their experience during Covid times.

Please share a brief background of Ramsons

Ramsons is a 60 years old company started around the fifties. We are a proud made in India company with an international presence. We have three European joint venture collaborations and we manufacture 190 different products in four state of the art production units in and around the south of India. We also have over 15 sales and service offices of our own and agents in about 40 countries.

We are the biggest manufacturers in Asia for sustainable laundry equipment, washer extractors, vertostar, garment dyeing machines, nano nebulizing machine, ozone machines, foam machines, steam ironing systems, storage systems, and a lot of other co-related products for the apparel trade.

What does sustainability mean to you as a company?

We at ramsons believe that the starting point of any product is not in the design but in its sustainability. We also believe in the five r’s of sustainability reduce, reuse, recycle, repair, and refuse. We also believe at ramsons that meaningful sustainability is the road to meaningful prosperity.

What are the main products of your company which enable sustainable garment production?

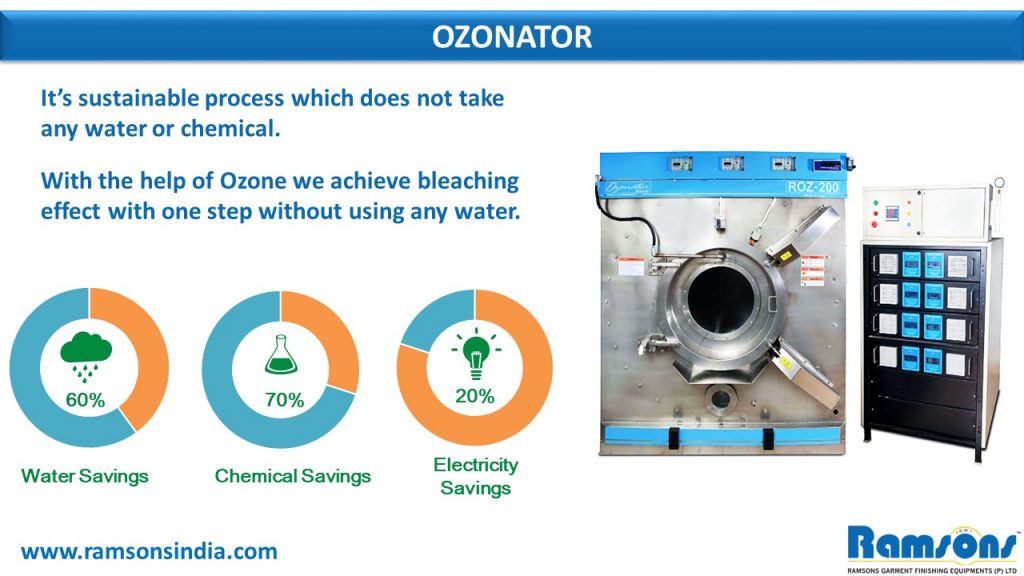

Sustainable products that we have been focusing on in the last decade have been ozone technology. The ramsons ozone equipment is internationally accredited by SGS as the safest and the most productive pure ozone technology available on the planet.

We also have nebulizing fog and foam machines that enable lower water requirements, lower chemical, lower energy requirements, and hardly any load on the effluent system. We’ve also got a conveyorized drying system as the dryer is the biggest consumer of energy in a laundry. And we have a system that uses air or natural drying to reduce about 80% of the drying power load. We also have an XDRUM technology where we realized that the only way to reduce stone powder or use of stone on jeans is by substituting it with another polymer that can be reused.

We tied up with Xeros in the UK and have developed the technology that reuses polymer but still creates the effect of no stone with lower water, lower chemical, and no load on the etp. These are some of the new products that we’ve come up with. We also have a lot more in garment finishing like the trouser topper made in collaboration with our German partner Veit.

Health is becoming so important. Have you come out with some health and wellness technological products?

Ramsons is proud to announce its foray into disinfection, sterilization, and medical devices and equipment. From cleanroom hygienic barrier washers technology to UV/ozone sterilization disinfection systems. From ethylene dioxide sterilization systems to oxygen generators. From steam sterilization to infrared systems. From nano anti-microbial to foam technology.

How has covid19 enabled you to reinvent your company

To give a company an entirely new angle of thinking along with sustainability we realized that sterilization and hygiene have become so important. Most of the equipment now also focuses on products necessary for covid-19 and also on hygiene and sterilization.

What are the main technologies you think will be used in the garment processing in coming years.

Technologies that can be used in the coming years are definitely those that will we use very little water hardly any chemistry, energy-efficient, little more robotic because the human labour is going to be hard to find and human labour transfer during covid is limited.

Any sustainability targets for your company ?

As a company, we want to give back to the earth what we have taken from the earth. This has been a sustainability target in all our products.

CONTACT RAMSONS AT : Info@ramsonsindia.com

Meet Ramsons Team and 30 other exhibitors at our SUSTAINABLE INTERPLAY event on Nov 23 from 11am Central Europe Time. Register at virtual.denimsandjeans.com/virtual and get your unique code to PRE SCHEDULE your FACE2FACE meetings with the exhibitors.