BluConnection is a leading producer of pre-reduced liquid indigo based out of Singapore. They recently launched a new process called NCD process (Nature Conscious Dyeing) which is based on their pre-reduced liquid Indigo DenimBlu36 AR and BluWit, an organic reducing agent. During the recently held Denimsandjeans Vietnam, we discussed with Alexander to know more about how it will help the industry.

Why did you feel the need to come out with the new NCD process ?

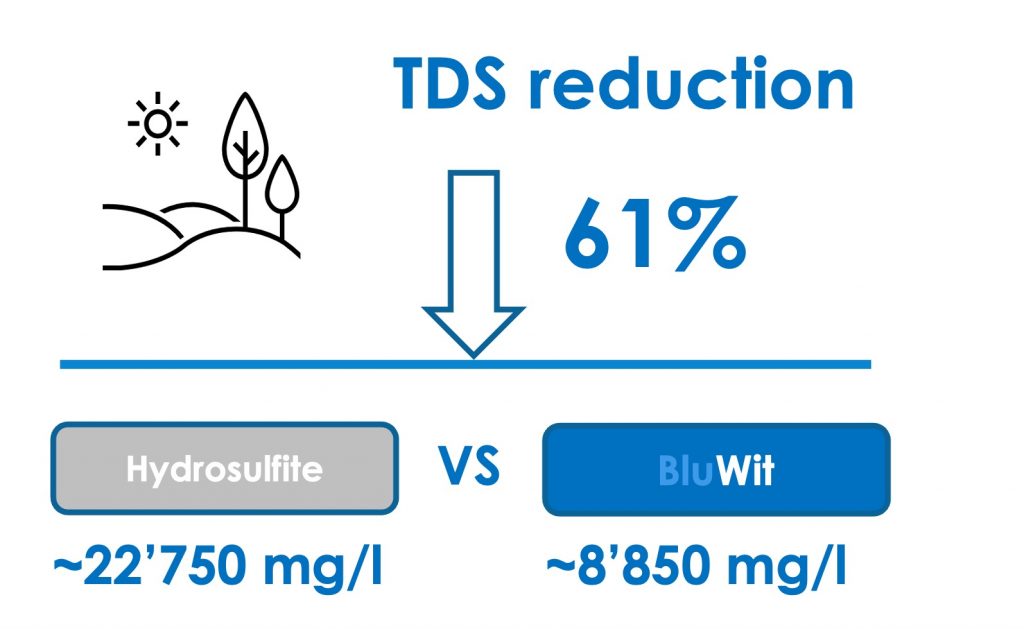

The NCD process (Natural Conscious Dyeing process) came a long way. The introduction of pre-reduced liquid Indigo was a big step forward to improve Indigo dyeing significantly, achieving better control and making it more sustainable. It allows us to reduce the amount of an inorganic, toxic chemical required for the reduction of Indigo (Hydrosulfite) significantly. Until today, a substantial amount of Hydrosulfite is required to keep the Indigo dyeing process stable. Not anymore! Bluwit allows us to replace Hydrosulfite completely, imagine Indigo dyeing without Hydrosulfite!

Hydrosulfite, being the standard reducing agent for the dyeing of Indigo, is contributing to the typical appearance of Denim with dark shades and ring-dyeing effect, yet it is also unstable in solutions and inorganic salt is generated and discharged into the waste water. Finding an alternative for Hydrosulfite which is ecologically sound and performing like Hydrosulfite was driving our team in BluConnection since our inception.

You mentioned that Bluwit is the first organic reducing agent. Can you tell more about it?

It is the first organic reducing agent which produces real denim with authentic washing effect without compromise on dye-build-up and dark shades are achievable with 5-6 dips. This is important for denim mills to be able to produce denim with the same or similar esthetics.

At the same time they can benefit from a reducing agent which is biodegradable in contrast to Hydrosulfite.

With Denimblu36 AR being a pre reduced indigo , what benefits in terms of commercials, sustainability and quality does it offer to mills and downstream garment producers?

We launched DenimBlu36 AR, which is 20% stronger than our original product DenimBlu30, enjoying a good response from the market. We are applying a purification process to reduce aniline. DenimBlu36 AR is our best product, reducing the CO2 footprint, meeting all retailer requirements effortlessly. At the same it is cost efficient. I ask myself, how cost efficient we should be to make everybody in the supply chain happy? – Today the Indigo cost for 1 pair of jeans is 6-9 cents!

When it comes to brands, what kind of advantage does it give them for their sustainability claims ?

Naturally brands can benefit from both our products, DenimBlu36 AR in combination with BluWit, as explained before, ticking all the boxes product wise and manufactured in our new green factory, which was inaugurated in 2022. Our factory is zero discharge, generating the majority of the required energy from solar panels and demonstrating with our “green wall” and green landscape our commitment to people and the environment. In view of upcoming supply chain regulations, it will surely support those brands, retailers and denim mills, who take their commitments towards a sustainable environment and people seriously.

What customers were you targeting with this new product at our Denimsandjeans Vietnam show?

The NCD process is suitable for every denim mill!

For more details , connect alexanderbock@bluconnection.com