H&M Foundation, a Global Change award winner has been supporting early-stage innovation since 2015 while giving opportunities to people whose ideas can bring a change in the fashion industry. Startups struggle immensely to gather the funding and support to be able to change the world as we know it. H&M Foundation makes sure the voices of these startups are heard.

We published the first part of this article last week where, we covered 4 flamboyant startups being supported by the H&M foundation. In this second part, we move forward and look at the other six start ups which are exponentially gathering attention.

- Fairbrics- which has developed the first synthetic fibre that has a net positive impact on the climate change

- Green Nettle Textile- which uses resilient stinging nettles to produce linen-like fabrics

- Reverse Resources- which plans to create a platform for mapping, creating a platform for mapping

- Adetex.id- which created a thin RFID thread that can be filled with information and then sewn into a garment

- Unspun- which created virtual body scans to find the perfect fit of jeans

- Algaeing- which made a biodegradable and renewable thread and dye that has a smaller environmental footprint than most natural fibres

All these start ups have great potential in the field of sustainability and with the support of the H&M Foundation and their dreams are about to come true soon.

“We have worked with innovators for many years now and their biggest hurdle to realiz[ing] their ideas is funding and support to build scalable technology solutions,” Diana Amini, global manager of the H&M Foundation, said in a statement. “They also need collaboration partners like fashion brands and suppliers.”

From developing the first synthetic fiber that has a net positive impact on climate change to using resilient stinging nettles to produce linen-like fabrics, from creating a platform for mapping, steering, and tracing textile leftovers to reduce the need for virgin materials to creating a thin RFID thread that can be filled with information and then sewn into a garment, from creating virtual body scans to find the perfect fit of jeans to make a biodegradable and renewable thread and dye that has a smaller environmental footprint than most natural fibers, the next set of startups supported by H&M Foundation have such groundbreaking ideations that could change the fashion world as we know it.

FAIRBRICS

“By capturing carbon dioxide emissions from industrial fumes, fairbrics is developing the first synthetic fiber with the potential of having a net positive impact on climate change.”

The fashion industry is responsible for 10% of annual global carbon emissions, more than all international flights and maritime shipping combined, according to the World Bank. At this pace, the fashion industry’s greenhouse gas emissions will jump more than 50% by 2030, where manufacturing raw materials for polyester is a major source of emissions. Polyester, a synthetic fiber generally derived from petroleum or coal, stands for more than 65% of the textile and apparel industry’s fiber usage. Without a competitive alternative, the Paris Agreement of limiting global warming to well below 2 degrees Celsius will be hard to reach.

How does Fairbrics tackle this problem?

Fairbrics has developed a novel process to make polyester from waste CO², by capturing industrial fumes that would otherwise have been released into the air. This waste product is ten times less expensive than petroleum products and not only reduces CO² emissions but also uses the emissions as part of the solution. Shortly, the technology will produce carbon negative, 100% sustainable PET.

Business model

The business model will change over time. The long-term goal is licensing to have the most impact and long-term revenue with minimum investment. To do so, Fairbrics needs to demonstrate that the solution is cost-competitive when applied on a large scale.

The support required

Fairbrics requires $6,600,000 to convert its ideas into reality.

Competition

Fairbrics have only two alternatives. The first being petroleum-based PET which has a great demand in the market. The second is a fermentation-based fabric, where genetically modified bacteria is used to digest greenhouse gases and convert them into chemicals that can be used for plastic production. Still, Fairbrics’ business model and product are so different from both these alternatives that there is no concrete competition.

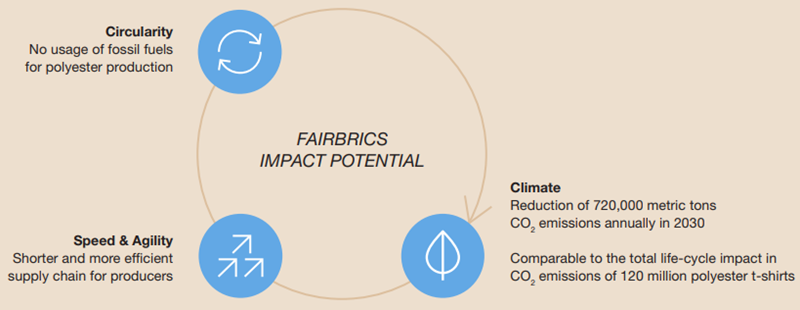

Fairbrics’ impact potential according to Accenture

- No usage of fossil fuels for polyester production

- The shorter and more efficient supply chain for producers

- Reduction of 720,000 metric tons CO2 emissions annually in 2030

GREEN NETTLE TEXTILE

“Using resilient stinging nettles to produce linen-like fabrics, green nettle textile offers an environmentally friendly alternative to conventional fabrics while also providing income and livelihood to hundreds of farmers across Kenya.”

The population of Kenya is on the rise. Most villages in Kenya have textiles that cause high levels of carbon emissions while using land and water. This land could’ve instead be used for farming and growing crops, hence also giving employment opportunities to the growing population.

How does Green Nettle Textile solve this problem?

Green Nettle Textile wants to reduce the demand for cotton and conventional textiles, and limit the environmental impact from new and second-hand clothes. By working with local farmers, it has established organic stinging nettle plantations on the non-productive slopes. This doesn’t only help in solving the problem of environment hurting fabrics but also helps in employing the farmers.

Business model

Green Nettle Textile produces eco fibers and woven products from nettle fibers, which are sold to retailers, simultaneously providing jobs, training, and nutrients to hundreds of smallholder farmers across Kenya.

The support required

Green Nettle Textile requires $60,000 to convert its ideas into reality.

Competition

Their primary competition is a cooperative society which deals with wool spinning, weaving, and makes handicrafts. Globally, some secondary competitors produce nettle fiber. But Green Nettle Textile definitely has an upper hand as the climatic conditions in Kenya are just perfect for production all year round.

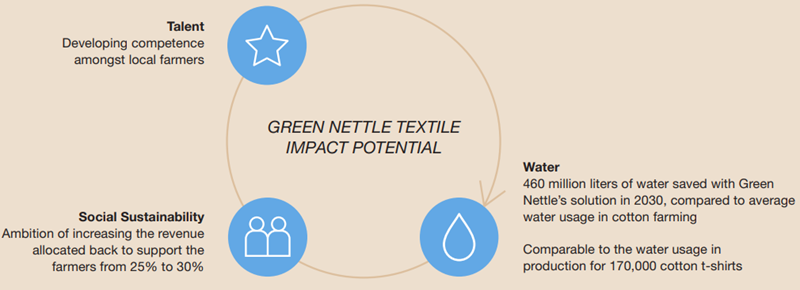

Green Nettle Textile’s impact potential according to Accenture

- Developing competence among local farmers

- The ambition of increasing the revenue allocated to support the farmers from 25% to 30%

- 460 million liters of water saved with Green Nettle’s solution in 2030, compared to average water usage in cotton farming

REVERSE RESOURCES

“Seeing data and digitalization of waste flows as key to a circular economy, reverse resources has created a platform for mapping, steering and tracing textile leftovers to reduce the need for virgin materials.”

A lot of fibers enter the fashion value just to end up as a fashion waste throughout the different stages of production from fiber, yarn, and fiber to fabric. This waste is just that, “waste”, it is not repurposed or recycled, and is just pushed out for the informal sector (people like waste pickers) to take care of, without any transparency. In short, we have no clue how much waste goes where. At the same time, 111 million metric tons of new fibers were produced globally in 2019 and by 2030 it’s expected to rise to 146 million if business continues as usual (Textile Exchange). This is an equation that doesn’t add up. And there’s no data to cover the exact size of the problem.

What is Reverse Resources’ plan of action?

This Estonia-based company believes data of material flows is the most valuable resource for the age of circular economy. With their mapping and tracking platform for textile waste, they provide 360-degree transparency of the waste flows. The platform is like an Uber of textile waste, connecting supply with demand, and only then suggesting the best route to it.

Business Model

Reverse resources use the processes of waste management as ground rules and bring down the cost of sourcing and help in increasing the quality of waste for recycling. They have 3 main services-

- Waste mapping services across a large number of producers to identify secondary materials and current disposal methods as well as enabling strategic planning and tracking of KPIs

- Sourcing, supply chain management, and 360-degree tracking of waste: matchmaking, order management, support of waste delivery, and verifying of the material streams.

- Trading of secondary materials: marketplace as a last resort for secondary material flows.

The support required

Reverse resources require $120,000,000 to convert its ideas into reality.

Competition

It does not have any specific competitions as it is the first of its kind.

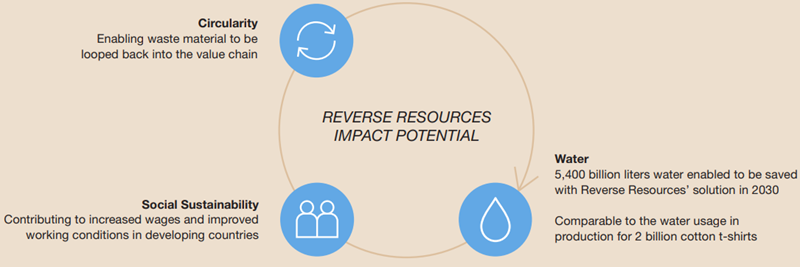

Reverse Resources’ impact potential according to Accenture

- Enabling waste material to be looped back into the value chain

- Contributing to increased wages and improved working conditions in developing countries

- 5,400 billion liters water enabled to be saved with Reverse Resources’ solution in 2030

ADETEX.ID

“Through a thin RFID thread that can be filled with information and then sewn into a garment, and then remains viable throughout the garment’s lifecycle, ADETEX.ID opens up for new possibilities within, for example, textile recycling, stock management, and second-hand solutions.”

Ellen MacArthur Foundation states that out of the billions of garments that are produced every year, less than 1% of the material used to produce clothes is recycled into new garments, which leads to a loss o0f more than 100 billion USD worth of materials every year. One of the biggest barriers to large-scale recycling is that most garments are made of blended textiles. To fully recycle these garments, the material composition must be known – which it rarely is today.

What is ADETIX.ID’s plan to solve this?

Adetex.ID wants to break this outdated linear model and shift it into a circular one where garments are kept in a loop. The RFID thread stores the content information of a garment, which enables automated sorting and recycling. With this solution, textile waste can be circulated back into the system, significantly reducing dependency on virgin resources.

Business Model

ADETEX.ID is going to produce and develop the RFID thread while working with global sales partners that sell directly to the fashion industry. They are going to target leading fashion and apparel retailers, along with several actors across the supply chain who want to improve transparency and recyclability. They can customize the thread according to the customers’ requirements.

The support required

ADETEX.ID requires $13,700,000 to convert its ideas into reality.

Competition

Several other actors produce RFID technology for the fashion industry. The most common RFID tags are attached to the garment as a hangtag or sticker and are removed at the point of sale. Adetex.ID has a unique market-leading position, as the RFID Thread® is the industry’s first RFID sensor in the form of a thread that is designed to survive the entire product lifecycle, including washing.

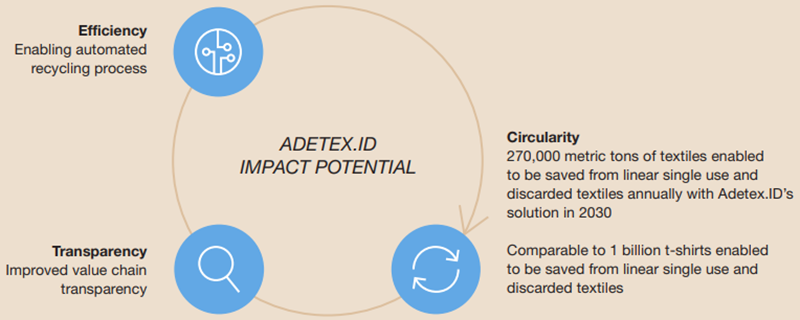

ADETEX.ID’S impact potential according to Accenture

- Enabling automated recycling process

- Improved value chain transparency

- 270,000 metric tons of textiles enabled to be saved from linear single-use and discarded textiles annually with Adetex.ID’s solution in 2030

UNSPUN

“By stopping the guessing game and instead of selling jeans before making them, unspun creates bespoke jeans with a perfect fit based on algorithms from a body scan. this eliminates the need for inventory and reduces waste, while also changing the way fashion is designed and produced”

We all have so many clothes in our closets that we don’t wear and so many clothes that we end up throwing away at the end of the year. Multiple garments are not even sold and hence, never worn. Overproduction is quite a big issue in the fashion industry.

What is Unspun’s solution for this?

We all wear the perfect fitted jeans more than we wear the flawed at the waist or lose at the butt jeans, and Unspun plans to make just that. Instead of using the traditional sizes that you’d have to choose, it uses your exact body measurements with a body scan to make the perfect pair of jeans for you, and that too at a fraction of the typical cost of custom-made clothing.

Business Model

The unspun business model stands on three pillars:

- To solve a major consumer pain point through perfect jeans, while reducing garment waste.

- To rapidly scale the on-demand model by collaborating with the most ambitious fashion companies.

- To use that scale to set up micro-factories based on the proprietary world’s first 3D-weaving technology to make the process as cost and time-efficient as possible.

The support required

Unspun requires $25,000,000 to convert its ideas into reality.

Competition

Unspun has no primary competition as it’s the first of its kind.

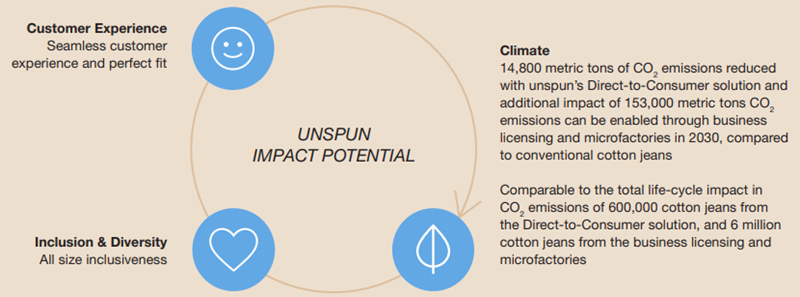

Unspun’s impact potential according to Accenture

- Seamless customer experience and perfect fit

- All size inclusiveness

- 14,800 metric tons of CO2 emissions reduced with unspun’s Direct-to-Consumer solution and the additional impact of 153,000 metric tons CO2 emissions can be enabled through business licensing and micro-factories in 2030, compared to conventional cotton jeans

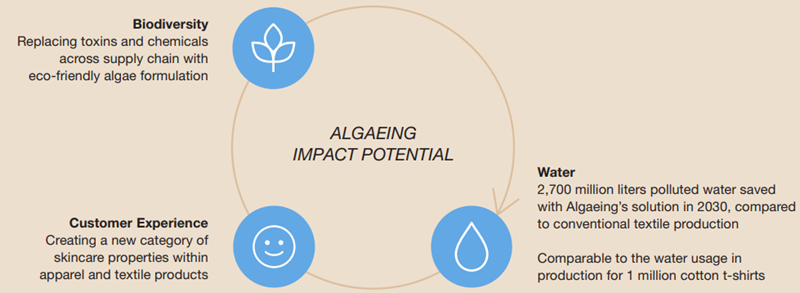

ALGAEING

“Powered by the game-changing microorganism algae, algaeing makes biodegradable and renewable thread and dye that has a smaller environmental footprint than most natural fibers and is easy for the industry to adopt. in addition, it creates a new category of products with benefits for the skin.”

Conventional fabric production and textile dyeing cause irreversible environmental damage and deplete precious natural resources, such as land and water. Producing 1 metric ton of cotton fabric, for instance, requires 200 metric tons of water. In addition, growing conventional materials, such as cotton, requires large amounts of pesticides that negatively impact biodiversity, while textile dyeing leads to dire consequences both in terms of water use and pollution.

How does Algaeing solve this?

This plant-based, renewable, and the biodegradable aquatic plant is a sustainable raw material that can be vertically farmed on land and turned into environmentally friendly textile fiber and dye. This innovation enables a paradigm shift towards Algaeing’s vision of Triple Good Solutions: good for the planet, the industry, your skin, and body – across the apparel and textile industry.

Business Model

Revenue will come from formulations, unit sales, and transactions of co-branded products. With a focus on the fashion industry, the current main markets are the fiber and colorant markets. However, Algaeing can lead transformation in multiple industries due to their unique patented formulations.

The support required

Algaeing requires $5, 00,000 to convert its ideas into reality

Competition

Algaeing has two types of competitors: existing fibers and dyes as well as plant-based alternatives. Algaeing stands out in terms of its drop-in solution that keeps down conversion costs since existing conventional production machinery can be used and there is no need for changing work processes nor employing new staff.

Algaeing’s impact potential according to Accenture

- Replacing toxins and chemicals across the supply chain with eco-friendly algae formulation

- Creating a new category of skincare properties within the apparel and textile products

- 2,700 million liters polluted water saved with Algaeing’s solution in 2030, compared to conventional textile production